We turn your idea into a successful product.

You have a challenge or an idea, while we have the expertise to transform it into successful solutions.

Many successful products are the result of a desire to improve something that already exists, identify new possibilities in relation to an unsolved problem, or explore new technological, economic, or ergonomic methods.

SCHÖLLY develops intelligent solutions for use in the area of quality assurance of complex mechanical components and non-destructive testing-solutions to increase the long-term productivity and competitiveness of our customers.

For the area of maintenance, repair and overhaul, we develop visualization solutions to be integrated in the customer‘s inspection and repair processes. Damage inside equipment, caused by daily operation, is both detected and promptly rectified.

In doing so, we offer our customers and partners more than simply fulfilling standards. We maintain a dialog to identify specific requirements and seek out the best possible solution. We always pursue the goal of developing innovations and solutions that offer both technological and economic advantages. The result of this close cooperation are trail blazing products.

Visualization PLUS - More than just Visual Inspection

Innovative visualization solutions combine optical control with necessary repairs and thus ensure the best efficiency in maintenance.

Visualization PLUS is the new offering that stands for innovative solutions with extra functions. The innovative solutions distinguish from classic endoscopy and combine visual inspection with necessary repair work. In this way it is possible to carry out repairs cost-efficiently in situ under endoscopic view.

Endoscopic components in complex image processing systems

Several systems for different customers in different applications are currently undergoing final on-site testing at the end customer. Not all tests have been completed yet, but so far the systems have proven themselves excellently under very different environmental conditions and have delivered the images required by the customers for further processing.

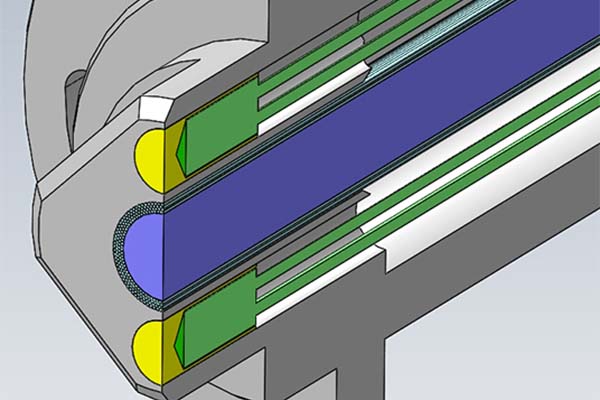

Fiberoptic assemblies and light guides for substance analysis

SCHÖLLY manufactures fiberoptic components according to customer drawings or develops the optimum solution for customer’s tasks.

We offer the whole program from one source: From the choice of the appropriate fiber, to the construction of an assembly, to the completion of a prototype, all the way to series production.