Successful special solutions from Schölly

Fiberoptic assemblies and light guides for substance analysis

When our customers come together with their application knowledge and experienced SCHÖLLY specialists with diverse technological know-how, innovative solutions are created.

SCHÖLLY manufactures fiber optic assemblies according to customer drawings or develops the optimal solution for the task specified by the customer. SCHÖLLY offers everything from a single source, from the selection of the suitable fiber to the complete construction of an assembly, the construction of a prototype to series production.

Fiberoptic sensors

With fiberoptic sensors a measured value is transferred not as an electrical signal, but as an optical one by using glass fibers. Fiberoptic sensors offer advantages over electric sensors: As no sensitive electronics are used, they can be utilized at high temperatures, with aggressive ambient substances or in electro-magnetic fields. They stand out for their robustness and reliability. Due to their small construction design they can be built in under confined space conditions. SCHÖLLY develops and manufactures components for fiberoptic sensors according to customers’ specifications and adapts them to the given installation situation.

Application example 1

Mobile analyzer for fluorescence analysis in field research.

SCHÖLLY supplies a special fiber optic in several variants for use on leaves, plants and corals.

Technical implementation

SCHÖLLY manufactures special fiber optics in different variants for mobile devices for fluorescence analysis in field research. For this application, a mixed fiber optic is connected to the spectrometer of the customer device. On the other side, there is a recording to fix leaves of plants in the field, for example, in order to carry out the measurement. The measurement results can be used to obtain information on photosynthesis in plants, e. g. to make a statement on the level of air pollution. A special variant is used in field tests in water to investigate corals.

Why SCHÖLLY?

- Supply of fiber optics exactly according to the customer’s specification

- High flexibility from SCHÖLLY for different variants even for smaller quantities

- Sound know-how in mixing and joining fibers

- Very long lifespan of the fiber optics even under harsh conditions in the field (e.g. use in salt water)

Application example 2

Microplate reader for substance / blood analysis using the methods DNA / RNA / protein quantification (HIV research, forensics, detection of antibodies).

SCHÖLLY supplies the light guides for “bottom-up” testing for UV / VIS spectroscopy.

Technical implementation

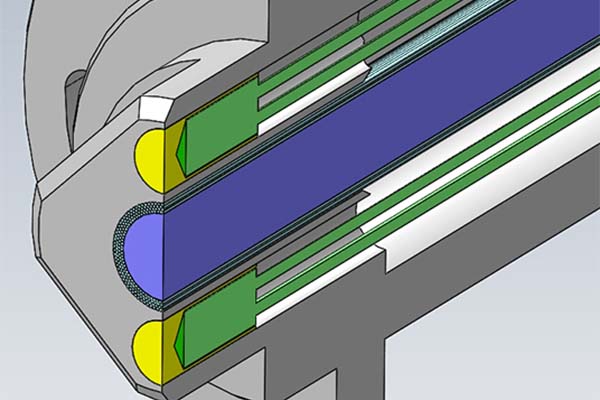

SCHÖLLY manufactures a special two-arm fiber optic for “bottom-up” illumination, in which the fibers in the sensor head are mixed. Quartz fibers are used that allow light transmission over a wide spectral range (UV/VIS) and ensure an almost even transmission over the entire range. The challenge lies in the very short mixing distance for a quartz fiber bundle and the compound, which must not develop autofluorescence. The fiber optic is adapted to the customer’s existing inputs to ensure optimal transmission. The sensor head is small and compact.

Why SCHÖLLY?

- Development know-how for complex compact designs

- Experience in the blending of quartz fibres

- Advanced joining technology

- Kurze Entwicklungszeit vom Prototypen zur Serie

Application example 3

Analysegerät für die Bioanalytik im UV/VIS Bereich. Anwendungen dieser Geräte sind in der Forschung, Entwicklung und Herstellung von Antikörpern, Medikamenten und Impfstoffen zu finden.

SCHÖLLY supplies a ring light for excitation in the UV / VIS range.

Technical implementation

SCHÖLLY develops and produces a customer-specific ring light for top-down illumination of samples in the VIS spectral range. The ring light is mixed and serves for optimal and homogeneous illumination of the samples. The required color spectra are generated with color filters.

Why SCHÖLLY?

- Development of the ring light according to exact customer specifications

- Very homogeneous illumination especially for larger dimensions

- Numerous other fiber optic components from SCHÖLLY are already in use at the customer’s premises

Additional information

Where are SCHÖLLY products used? What practical tips are there for the various areas of application? Find out more about this in our expertise area.

Areas of application

Our endoscopes, inspection systems and customer-specific solutions support our customer‘s value creation

process in various industries.

Application examples

Whether for manual spot checks or 100 % inspections – first-class inspection results will give you useful information about the internal condition of your components.

Industry Report

A look behind the scenes: customer-specific developments, from requirements to practical use in an industrial environment.

Technology

Our customers contribute their knowledge of the market; we offer a wide range of technologies for the implementation in marketable products.