Technical Endoscopy

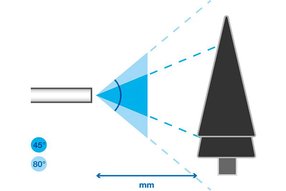

In order to detect potential defects at an early stage, SCHÖLLY develops products and solutions that provide users with meaningful images of the interior of complex components and systems.

Areas of application

Our endoscopes, inspection systems and customer-specific solutions support our customer‘s value creation process in various industries.

Defective workmanship, scratches, cracks, burrs or deposits in manufactured parts or during maintenance can be identified, corrected and the sources of defects eliminated at an early stage.

Quality assurance in production

Non-destructive visual inspection of components and components.

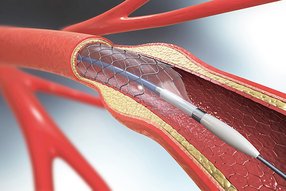

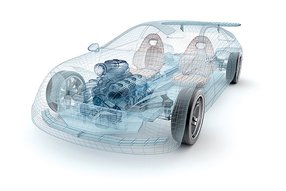

Automotive

Inspections of engine, turbocharger, injection and braking systems.

Aviation and Aerospace

New endoscopic solutions support the on-wing maintenance.

Energy / Power Plants

Different inspection systems for visual inspection.

Application examples

In manufacturing companies, our products contribute sustainably and efficiently to product quality through non-destructive visual inspection.

Whether for manual spot checks or 100 % inspections – first-class inspection results will give you useful information about the internal condition of your components.

Industry Report

A look behind the scenes: customer-specific developments, from requirements to practical use in an industrial environment.

Which products and methods enable reliable decisions in everyday testing practice? Our guides and info videos show the different options.

Technology

SCHÖLLY is the competent OEM partner when it comes to the development of individual visualization systems with the latest technologies and innovative product features. Production, service and regulatory services are part of the complete package for our OEM customers.

Our customers contribute their knowledge of the market; we offer a wide range of technologies for the implementation in marketable products.